generator cooling system

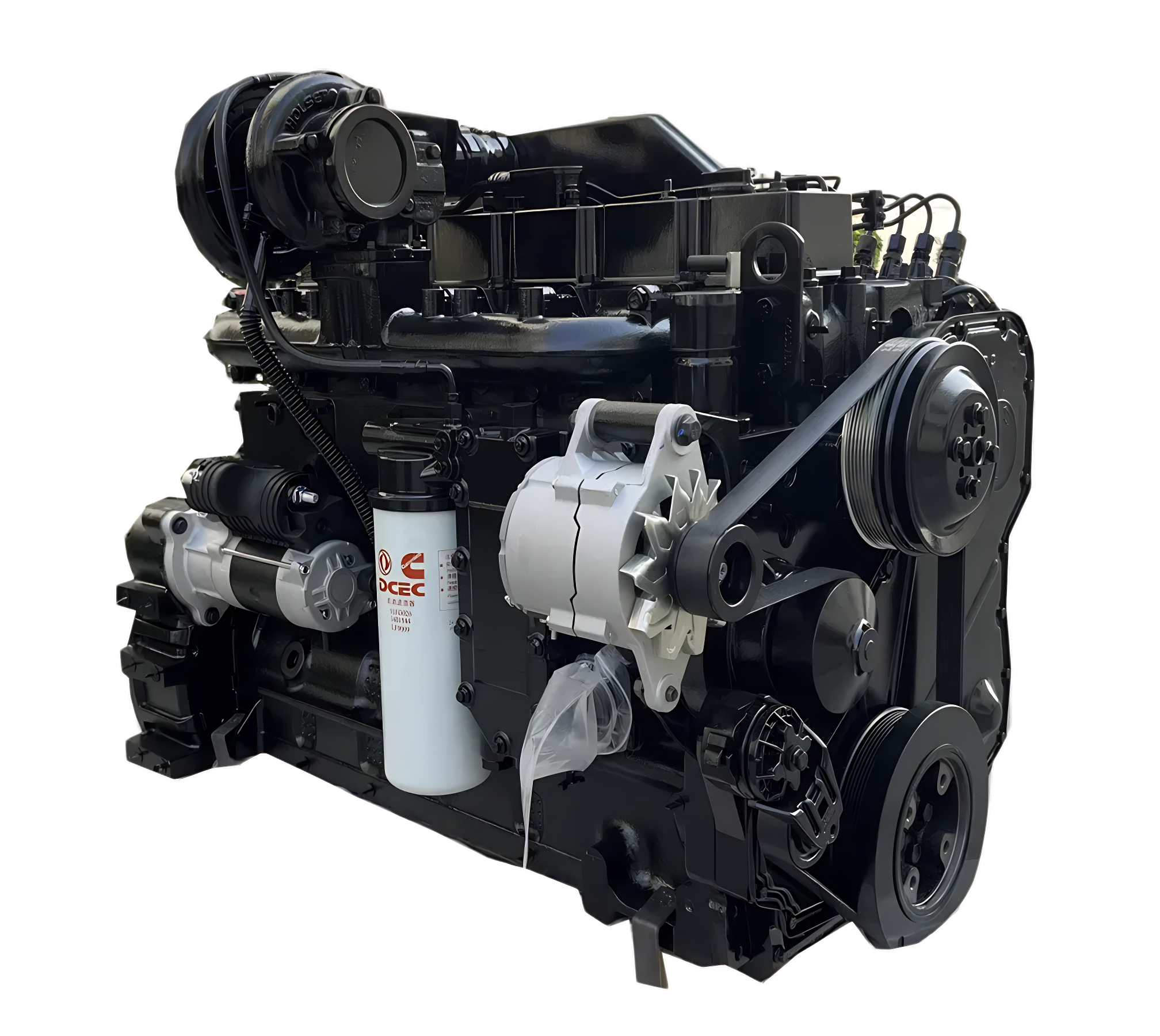

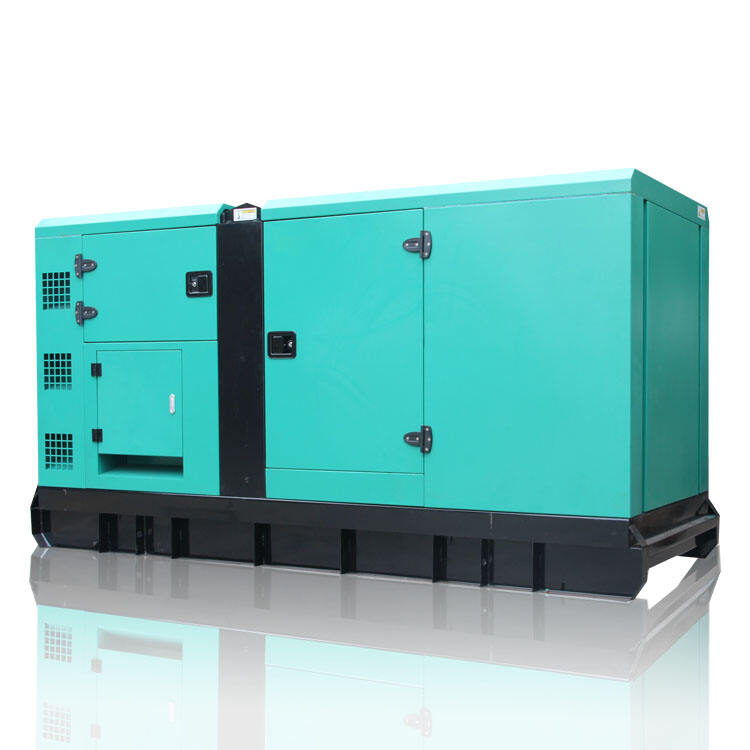

A generator cooling system is a sophisticated engineering solution designed to maintain optimal operating temperatures in power generation equipment. This critical system employs multiple cooling methods, including air cooling, liquid cooling, and hybrid approaches, to effectively dissipate heat produced during electricity generation. The primary components typically include radiators, cooling fans, heat exchangers, and advanced temperature sensors that work in concert to regulate thermal conditions. These systems are engineered to provide consistent temperature control across various load conditions, ensuring the generator maintains peak performance and longevity. The technology incorporates both closed-loop and open-loop cooling circuits, depending on the specific application requirements. Modern generator cooling systems utilize smart monitoring capabilities that continuously assess temperature levels and adjust cooling parameters automatically. These systems are essential in various settings, from industrial power plants to backup power installations, where they prevent overheating and maintain operational efficiency. The design also considers environmental factors, implementing eco-friendly coolants and energy-efficient operation modes that reduce the overall carbon footprint while maintaining optimal cooling performance.