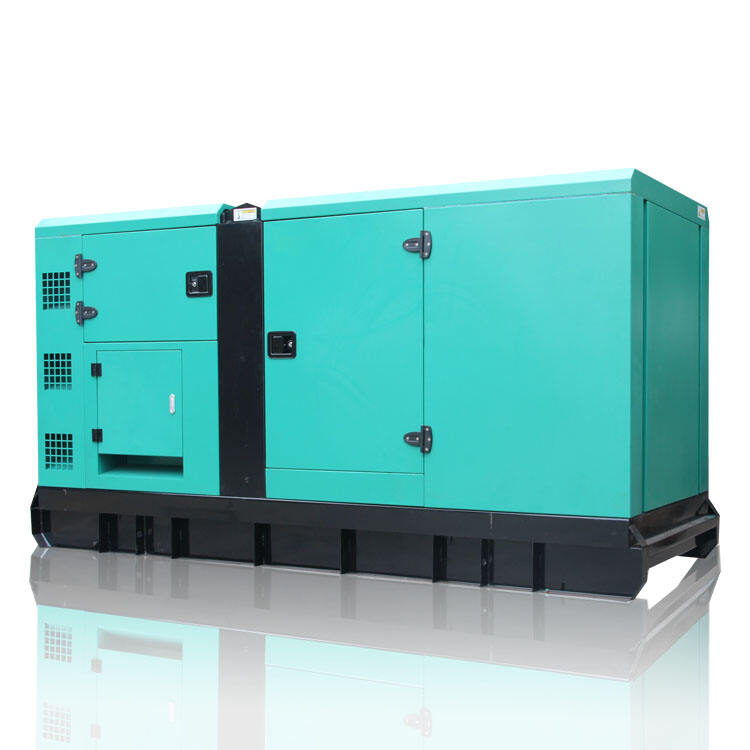

power generator motor

A power generator motor serves as the cornerstone of reliable electrical power generation, combining advanced engineering with practical functionality. This essential component converts mechanical energy into electrical power through electromagnetic induction, ensuring a steady power supply for various applications. The motor features precision-engineered components, including a rotor, stator, and sophisticated cooling systems that work in harmony to maintain optimal performance. Modern power generator motors incorporate smart monitoring systems that provide real-time performance data, allowing for predictive maintenance and enhanced operational efficiency. These motors are designed with variable speed capabilities, enabling them to adjust output based on demand while maintaining consistent frequency and voltage levels. The integration of advanced materials in their construction ensures durability and resistance to thermal stress, while innovative insulation systems protect against electrical faults. Power generator motors find applications across diverse sectors, from industrial facilities and commercial buildings to residential backup power systems. They're engineered to operate under various environmental conditions, featuring robust protection against dust, moisture, and temperature fluctuations. The latest models also incorporate energy-efficient designs that optimize fuel consumption and reduce operational costs.