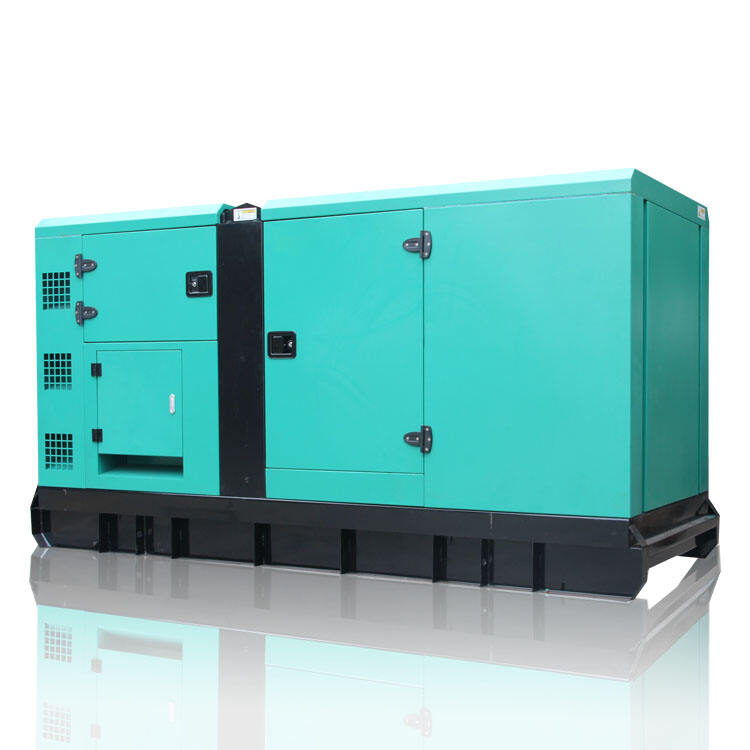

genset

A genset, or generator set, represents a comprehensive power solution that combines an engine with an electric generator to produce electrical energy. This sophisticated piece of equipment serves as a reliable power source in various scenarios, from emergency backup to primary power generation. Modern gensets incorporate advanced electronic control systems that monitor and regulate output parameters, ensuring consistent power delivery regardless of load variations. These units feature automatic voltage regulators (AVR) that maintain stable output voltage, fuel-efficient engines that optimize consumption, and sophisticated cooling systems that prevent overheating during extended operation. The versatility of gensets makes them indispensable in multiple applications, including construction sites, hospitals, data centers, and remote locations where grid power is unavailable. They come equipped with soundproof enclosures that significantly reduce operational noise, making them suitable for urban environments. Additionally, contemporary gensets integrate smart monitoring capabilities that enable remote management and predictive maintenance, enhancing their reliability and operational efficiency.